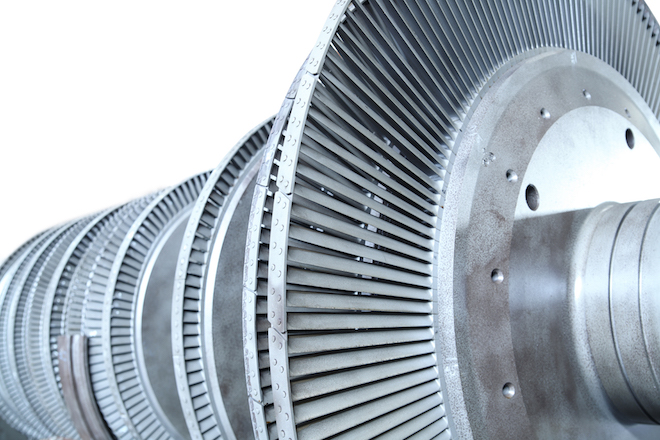

A-INTEGRA is a company specializing in the design and implementation of integrated solutions in the field of automatic control of industrial turbines, anti-surge control and protection of centrifugal compressors, monitoring of rotating equipment condition.

The scope of A-INTEGRA knowledge and experience application is quite extensive and covers almost all industries where rotating equipment is operated. (Oil and Gas Production / Transportation / Oil refining / Metallurgy / Chemicals / Petrochemicals / Thermal Power / Hydropower).

We focus on our customers’ needs and always offer them best engineering and commercial solutions only at all stages: from front-end engineering design to actual implementation.

A-INTEGRA is a company specializing in the design and implementation of integrated solutions in the field of automatic control of industrial turbines, anti-surge control and protection of centrifugal compressors, monitoring of rotating equipment condition.

The scope of A-INTEGRA knowledge and experience application is quite extensive and covers almost all industries where rotating equipment is operated. (Oil and Gas Production / Transportation / Oil refining / Metallurgy / Chemicals / Petrochemicals / Thermal Power / Hydropower).

We focus on our customers’ needs and always offer them best engineering and commercial solutions only at all stages: from front-end engineering design to actual implementation.