A-INTEGRA has managed to rank among leaders in the upgrading of steam turbine automatic control systems within a short time.

An integrated approach offered by A-INTEGRA when upgrading steam control systems and their assemblies is based primarily on a detailed turbine inspection. We use inspection results to provide optimal upgrade engineering solutions to our customers for discussion.

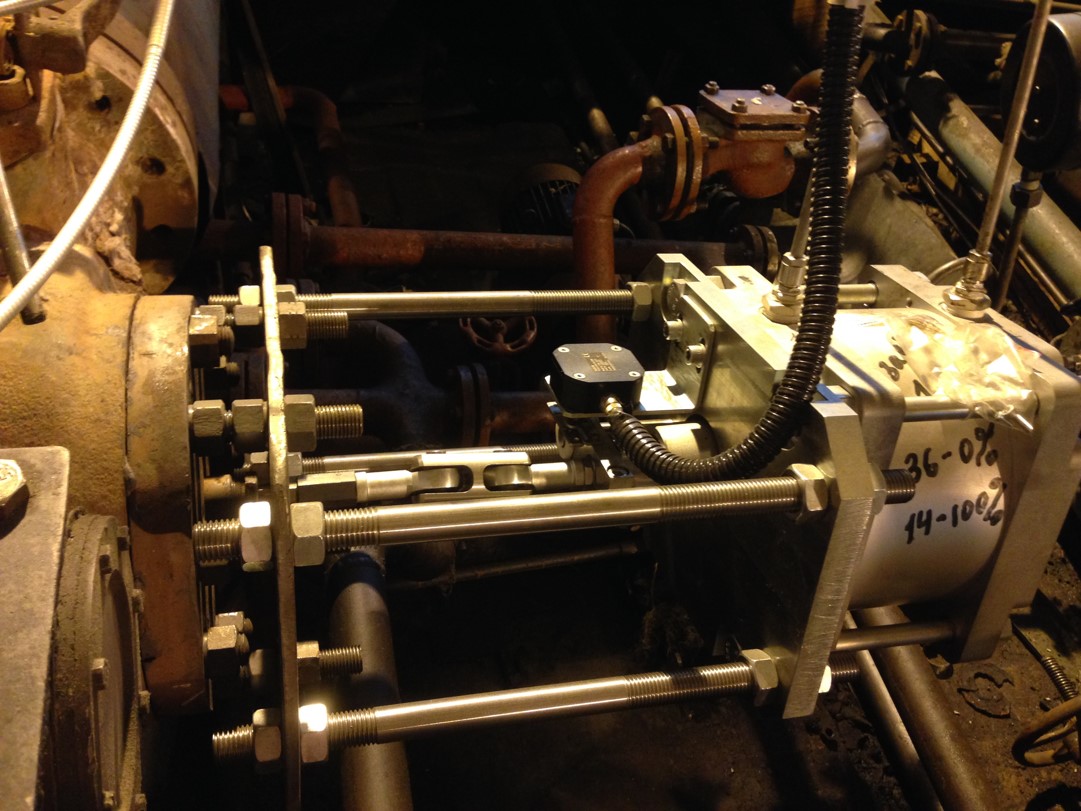

During inspection, we analyze hydraulic system, steam system and steam turbine mechanics condition and thoroughly check individual assemblies of these systems such as actuating cylinders, pilot valves, existing control circuits, instrumentation, mechanical protection, gas headers, oil drain solenoids, oil quality. We identify installation options for rotation speed sensors, check steam valve opening/breakaway force calculations, ensure preliminary engineering of steam valve drive upgrade/replacement, specify steam pressure limits, locate fluid circuit “blind-off” points, etc.

A-INTEGRA provides its customers with a selection of field-proven Woodward, Voith hydraulic actuators and transducers, Camozzi pneumatic actuators, Diakont, Exlar electromechanical actuators as steam turbine control drives for various applications and environments. At customer’s option, A-INTEGRA can apply actuators by any other manufacturers if their specifications meet response time and control quality requirements as well as existing technical conditions.

We have a successful experience in implementing steam turbine automatic control systems with GE, Honeywell, Woodward, Schneider Electric, Siemens platforms used as medium/high levels of such a control system.

A-INTEGRA recommends widely used and time-proven Bently Nevada and Woodward Protech systems to be used when implementing certified electronic overspeed protection systems for steam turbines compliant with world standards.