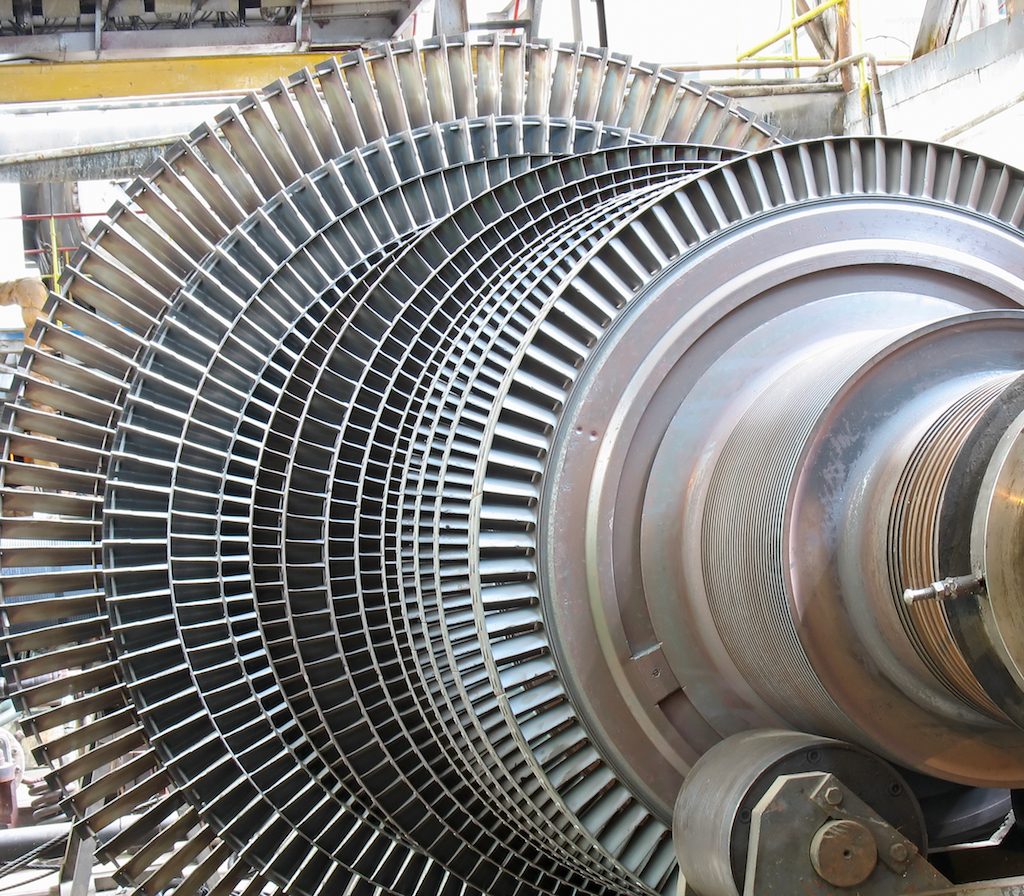

Rotating equipment condition monitored maintenance is based on continuous checks and periodic technical diagnostics performed to determine a number of machine condition parameters and therefore obtain a complete set of data required to ensure reliable forecasting of failure probabilities for certain machine assemblies. The customer uses monitoring and diagnostics results as a basis for making decisions on whether repair is required or not, the time and scope of repair as well as the time of the next condition monitoring.

For our customers, condition monitored maintenance means:

- Improved efficiency of expensive turbo machinery equipment operation.

- Significantly cut equipment maintenance costs .

- Less shutdowns.

- Less equipment failures..

Extensive experience gained as well as highly qualified engineering staff allows A-INTEGRA to offer its customers a new service – developing condition monitored maintenance concepts for their gas turbine equipment.

This concept provided by A-INTEGRA allows customers to:

- Forecast the period during which equipment will remain operational .

- Develop an operation chart and optimize the time required to replace assemblies and components that affect reliability and fail safety of turbo machinery equipment .

- Determine a list of materials and equipment required for repair..